AI-powered automation in the manufacturing sector: enhance efficiency

Anúncios

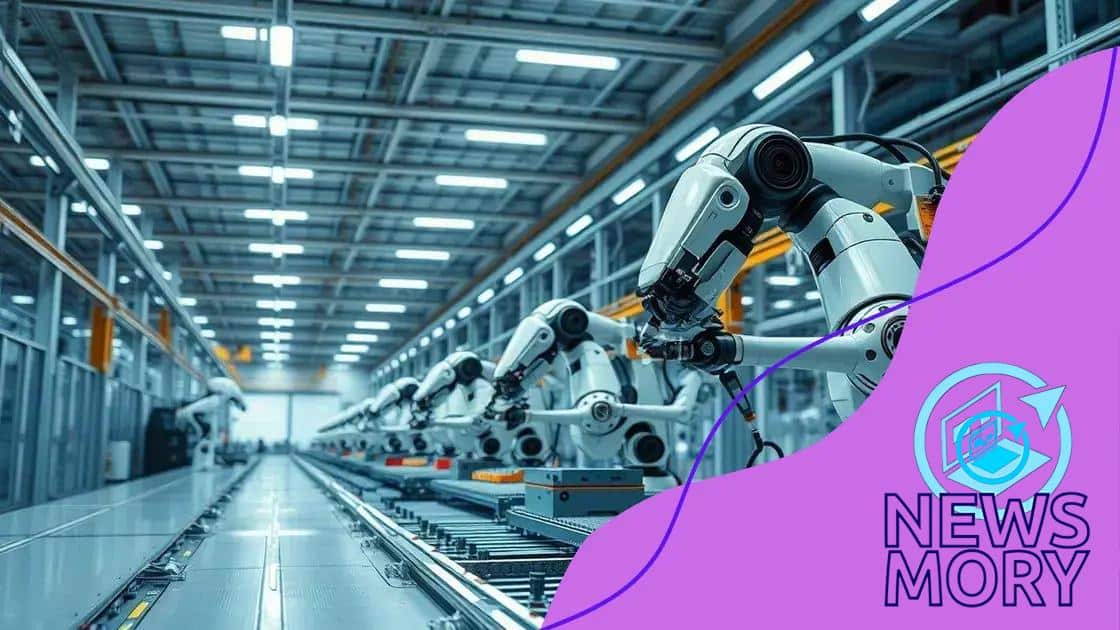

AI-powered automation in the manufacturing sector enhances efficiency, reduces costs, and improves product quality, while also presenting challenges like integration issues and employee resistance.

AI-powered automation in the manufacturing sector is changing how factories operate. Have you considered how this technology can streamline production and cut costs? Let’s dive into its transformative impact.

Anúncios

Understanding AI-powered automation

Understanding AI-powered automation is crucial for modern manufacturing. This technology integrates artificial intelligence with automated processes to improve productivity. With AI, machines can learn and adapt to new tasks efficiently.

What is AI-powered automation?

This involves using AI algorithms to automate processes that were previously done by humans. The system collects data, analyzes it, and makes decisions to optimize manufacturing operations. For example, AI can predict equipment failures before they happen, allowing for preventative maintenance.

Key features of AI-powered automation:

- Enhanced decision-making through data analysis.

- Improved accuracy and precision in tasks.

- Ability to learn from experience and adapt processes.

- Increased speed and efficiency in production.

AI-powered automation also helps in reducing human error, leading to higher quality products. By integrating AI into production lines, manufacturers can ensure consistency and reliability. The ability to monitor operations in real-time provides insights that were previously unattainable.

Anúncios

This technology not only boosts efficiency but also lowers operational costs. By automating routine tasks, human workers can focus on more complex problems. AI-powered automation opens new opportunities for innovation and growth within the manufacturing sector, reinforcing the importance of adapting to technological advancements.

Key benefits for manufacturers

The key benefits for manufacturers adopting AI-powered automation are numerous. Manufacturers can significantly enhance their production processes by integrating smart technologies. This adoption not only improves efficiency but also leads to better product quality.

Increased Efficiency

With AI, machines work faster and more accurately than human operators. Tasks that used to take hours can now be completed in minutes. The automation of repetitive tasks allows workers to concentrate on innovation.

Cost Reduction

AI-powered automation can lead to major cost savings. By minimizing human error and streamlining operations, manufacturers cut waste and reduce the resources needed to produce goods.

Predictive Maintenance

Another significant advantage is predictive maintenance. AI systems can analyze performance data and forecast when machines need servicing. This proactive approach prevents costly downtime and extends the lifespan of equipment.

- Enhanced data analysis for better decision-making.

- More consistent production quality.

- Improved supply chain management.

- Faster response times to market demands.

Moreover, AI-powered automation helps manufacturers adapt quickly to changes in product design or market trends. This flexibility is vital in today’s fast-paced industry. As technology continues to evolve, those who leverage AI will find themselves ahead of the competition.

Real-world applications in factories

Real-world applications in factories demonstrate how AI-powered automation is revolutionizing the manufacturing sector. Factories across the globe are implementing these technologies to optimize operations and enhance productivity.

Automated Assembly Lines

One of the most common applications is in automated assembly lines. Robots equipped with AI technologies work alongside humans to increase efficiency and reduce error rates. These robots can adapt to different tasks quickly, improving workflow and speeding up production.

Quality Control

AI plays a crucial role in maintaining high-quality standards. With advanced vision systems, AI can inspect products for defects faster than the human eye. This ensures that only products meeting strict quality requirements reach customers.

Supply Chain Optimization

Another application is in optimizing supply chains. AI algorithms analyze data to predict inventory needs, helping manufacturers avoid stock shortages or overproduction. This ability to predict demand accurately gives businesses a competitive edge.

- Robotic arms for precision tasks.

- Data-driven maintenance scheduling.

- Automated packaging processes.

- Predictive analytics for market trends.

Furthermore, companies are using AI to analyze production data, identifying areas where efficiency can improve. Insights extracted from this data enable manufacturers to adapt quickly to market changes, making them more agile.

Overall, the real-world applications of AI-powered automation in factories enhance not only productivity but also safety. These technologies help create a smarter and more efficient manufacturing environment, showing the potential of what AI can achieve.

Challenges of implementing automation

Implementing automation in manufacturing presents several challenges that companies must navigate. While AI-powered solutions offer significant benefits, understanding these obstacles is vital for successful integration.

Resistance to Change

One major challenge is employee resistance. Workers may fear job loss or feel uncertain about adapting to new technologies. Overcoming this requires effective communication and training programs to showcase the benefits of automation.

Integration with Existing Systems

Another hurdle is integrating new automation technologies with legacy systems. Many factories rely on older equipment that may not easily connect with AI systems. This can result in high costs and complexity during the transition.

High Initial Costs

Furthermore, the initial investment for implementing AI automation can be substantial. From purchasing new equipment to hiring expert staff, the costs can deter some manufacturers. However, it’s important to view these costs as an investment in long-term gains.

- Training needs for existing employees.

- Potential downtime during the transition.

- Need for continuous monitoring and updates.

- Data security concerns related to new technologies.

Additionally, manufacturers must consider data security and privacy. With AI systems handling vast amounts of sensitive information, ensuring robust cybersecurity measures is crucial. These challenges highlight the need for a well-structured plan when adopting AI-powered automation.

By addressing these issues proactively, manufacturers can harness the full potential of automation, creating a smoother transition while boosting productivity and efficiency.

Future trends in AI automation

The future trends in AI automation highlight significant changes in manufacturing. As technology evolves, so do the methods for enhancing production and efficiency. Manufacturers are increasingly adopting AI to stay competitive and meet consumer demands.

Smart Factories

One trend is the rise of smart factories. These facilities utilize interconnected devices that communicate with each other through the Internet of Things (IoT). This interconnectivity allows for real-time monitoring and analysis, helping to optimize processes and predict equipment failures.

Advanced Robotics

Another important trend is the development of advanced robotics. Next-generation robots will be more adaptable and capable of working alongside humans safely. They will learn from their environment and improve their skills over time, enhancing productivity.

- Increased use of machine learning algorithms.

- Integration of augmented reality for training and diagnostics.

- Greater focus on sustainability and eco-friendly practices.

- Enhanced cybersecurity measures to protect automated systems.

Moreover, AI will continue to improve decision-making processes. By analyzing vast amounts of data, AI systems will provide insights that help manufacturers optimize their supply chains and reduce costs. The emphasis will also shift towards creating more sustainable production methods, reducing waste, and using resources more efficiently.

Overall, the future of AI automation promises exciting advancements. By embracing these trends, manufacturers can enhance their operations, adapt to changing market conditions, and ensure long-term success.

As we look ahead, the role of AI-powered automation in the manufacturing industry will continue to grow. Embracing these advancements offers many benefits, such as increased efficiency, better quality control, and reduced costs. While challenges like employee resistance and integration issues exist, proactive planning and training can ease these transitions. Ultimately, the future trends point towards smarter, more sustainable factories that leverage technology to enhance production. By staying informed and adapting to these changes, manufacturers can not only survive but thrive in a competitive landscape.

FAQ – Frequently Asked Questions About AI-Powered Automation in Manufacturing

What are the main benefits of AI-powered automation in manufacturing?

AI-powered automation increases efficiency, improves product quality, and reduces operational costs.

What challenges do manufacturers face when implementing automation?

Common challenges include employee resistance, integration with existing systems, and high initial costs.

How will AI impact the future of manufacturing?

AI will lead to smarter factories, advanced robotics, and better decision-making processes.

Can small manufacturers also benefit from AI automation?

Yes, small manufacturers can adopt AI solutions tailored to their needs, leading to improved operations and competitiveness.